Polish Types in Fiber Optic Connectors

Now, let's look into how we can enhance security and reduce signal loss at the tip (polish) of the connector. Isn't it worthwhile to consider this given the importance of your data? Let's examine these concepts as they are integral to fiber optic connectors. We will discuss the different polish types in fiber optic connectors.

When a connector is installed on the fiber end, some loss will occur. Some light is reflected back down the fiber towards the light source that generated it, known as back reflections or Optical Return Loss (ORL). These back reflections can damage the laser light sources and disrupt the transmitted signal. Different polishing types of fiber connectors (indicating the tip of the connectors) result in different back reflections. These are mainly referred to as:

Flat Connector (FLAT)

Physical Contact Connector (PC)

Ultra-Physical Contact Connector (UPC)

Angled Physical Contact Connector (APC)

Flat Connector (FLAT)

The original fiber connector features a flat-surface connection or a flat fiber connector. The primary issue is that a small air gap between the two ferrules is naturally left when mated, partly due to the relatively large end-face of the connector that allows for slight imperfections. The flat fiber connector is not suitable for single-mode fiber cables with a 9µm core size, making it essential to evolve into Physical Contact (PC) connectors.

Physical Contact Connector (PC)

The Physical Contact connector is polished with a slight spherical design to reduce the overall size of the end-face, helping to decrease the air gap issue faced by Flat Fiber connectors. This results in lower Optical Return Loss (ORL) with less light being sent back towards the power source

Ultra-Physical Contact Connector (UPC)

The Ultra Physical Contact polish type involves more extensive polishing than the PC type, creating better contact and signal transmission. However, this polish type is not as robust as the PC polish type. Repeated connections and disconnections will cause surface degradation and ultimately reduce performance.

Typically, the UPC single-mode fiber connector is blue, while the UPC multimode fiber connector is beige (Note: 10G UPC multimode fiber connector is aqua).

While PC and UPC connectors have low insertion loss, the back reflection (ORL) depends on the surface finish of the fiber. The finer the fiber grain structure, the lower the back reflection. When PC and UPC connectors are continually mated and unmated, the back reflection will degrade over time, necessitating a connector that maintains low back reflection and can sustain repeated matings without ORL degradation.

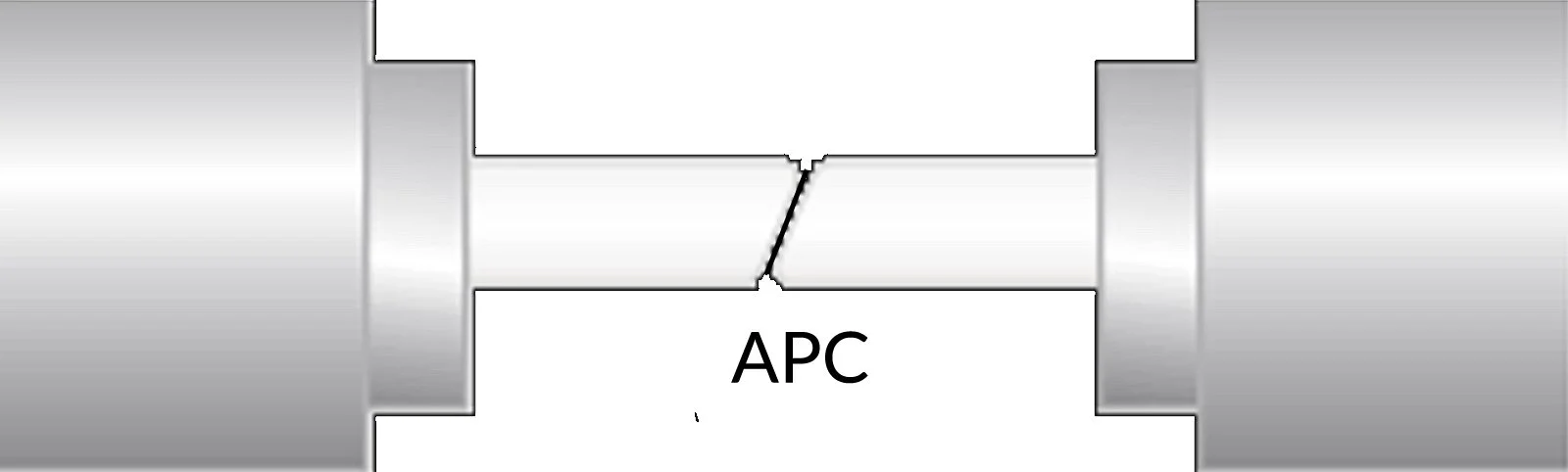

Angled Physical Contact Connector (APC)

Angled Physical Contact connectors have curved end faces angled at an industry-standard eight degrees, allowing for even tighter connections and smaller end-face radii. Any light redirected back towards the source is reflected out into the fiber cladding due to the 8° angled end-face. APC connector back reflection does not degrade with repeated mating/unmating. APC fiber connectors can only be used with single-mode fiber and are typically green.

So, Which One to Choose?

Understanding all the connector end-face options can be challenging, especially when considering cost, simplicity, and optical performance. Your specific needs will determine the best choice. For applications requiring high-precision optical fiber signaling, APC should be the first consideration. However, less sensitive digital systems will perform equally well using UPC.